Solution Heat Treatment Aluminum

Solution heat treatment aluminum. Solution heat treatment solution. The process of taking a 6061 aluminum part in O condition to a stronger more durable condition begins by heat treating the parts at 985 degrees Fahrenheit for an hour in a drop bottom furnace. The purpose of this is to dissolve all the alloying elements in a solid solution in the aluminum.

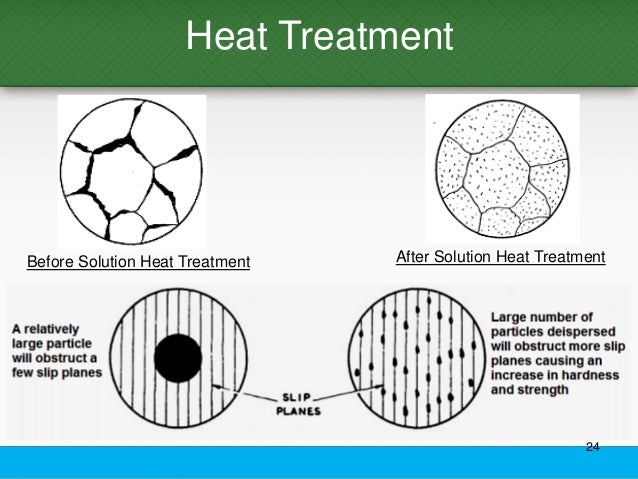

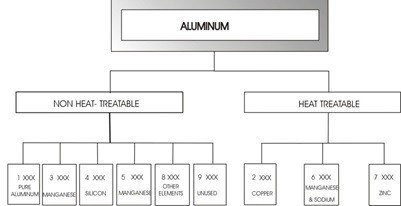

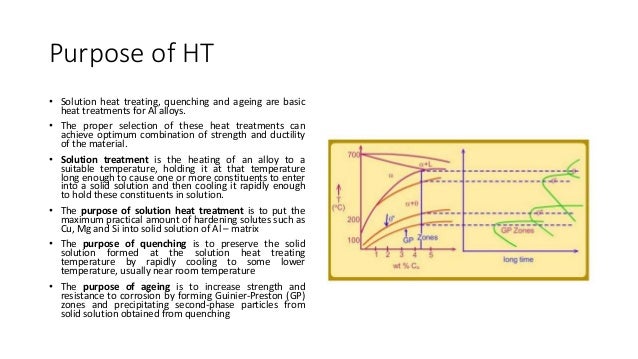

The main processing methods include hot working cold working solution heat treatment aging treatment annealing treatment etc. Heat Treating of Aluminum Alloys HEAT TREATING in its broadest sense refers to any of the heating and cooling operations that are performed for the pur- pose of changing the mechanical properties the metallurgical structure or the residual stress state of a metal product. Aluminum Heat Treating Aluminum Solution Heat Treat-ing Aluminum alloys are classified as either heat treatable or not heat treatable depending on whether the alloy responds to precipitation hard-ening.

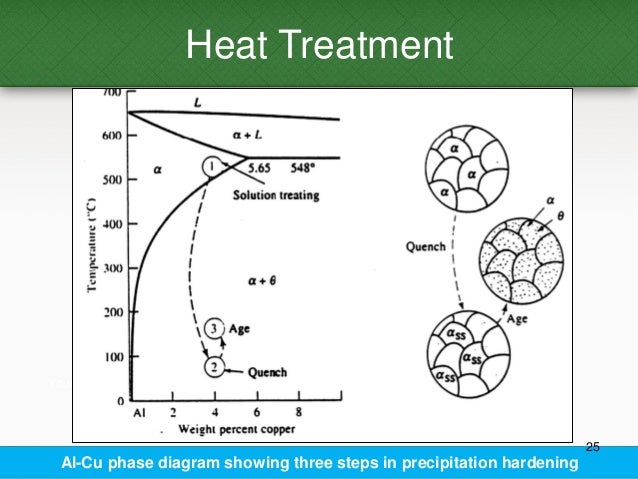

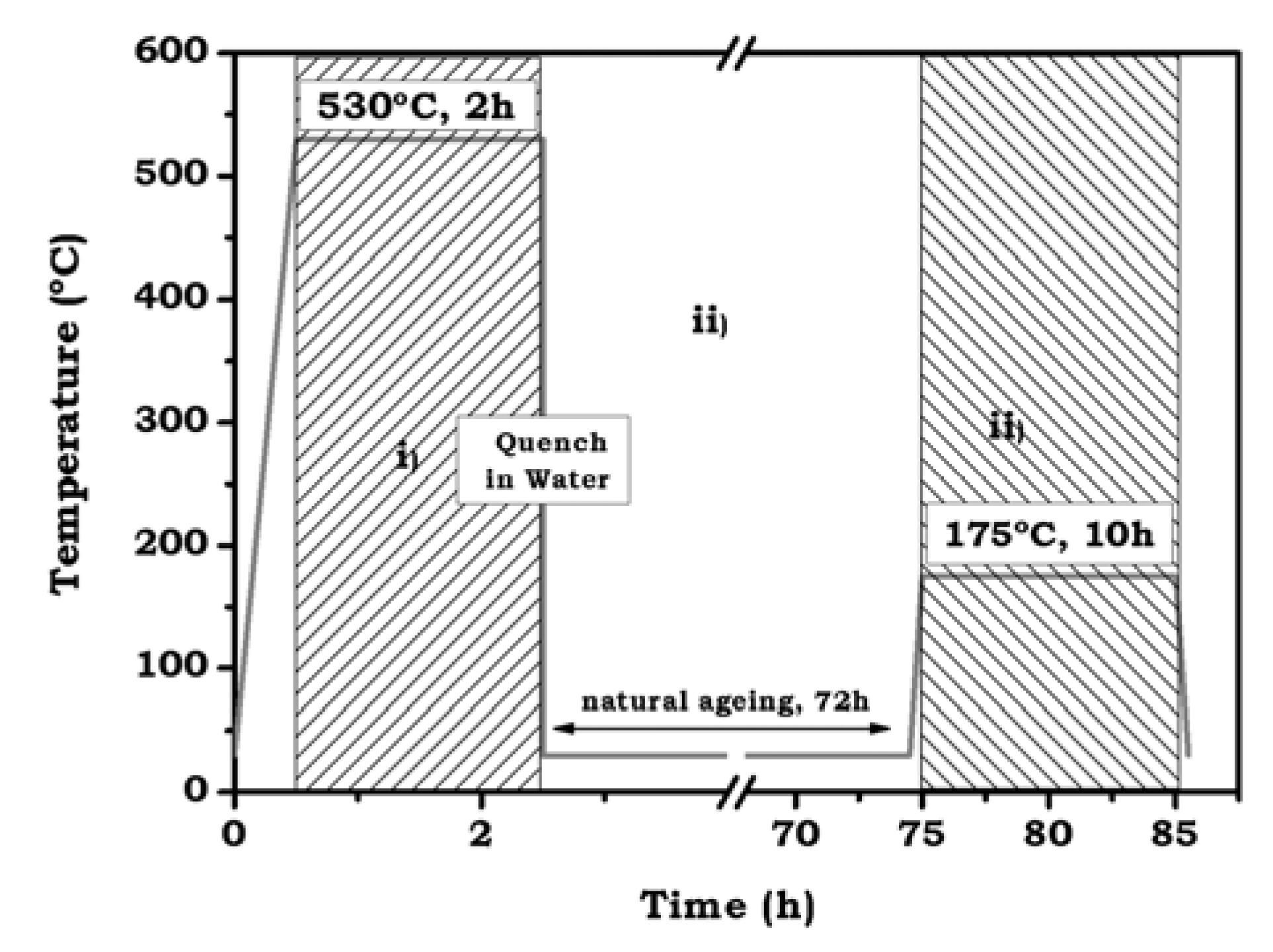

Strain hardening occurs when. This requires heating the material close to near the eutectic temperature and holding the material at temperature long enough to allow close to complete solid solution. Aluminum alloys are subject to work hardening also known as strain hardening.

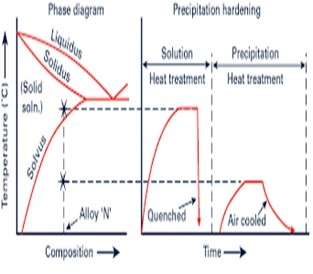

At that point the basket containing the parts is dropped into a quench tank. The solution heat treatment involves heating the alloy to a high enough temperature to drive the alloy - ing elements into solid solution yielding a metastable supersatu - rated solid solution. It is different in so much as the solution as treatment which involves heating the aluminium alloy up to its appropriate solution temperature followed by quenching rapidly this makes the alloy extremely soft.

According to different processing methods the aluminum alloy temper processed products can be summarized by aluminum. The general types of heat treatments applied to aluminum and its alloys are. In heat treatable alloy systems like 7XXX 6XXX and 2XXX the al-loying elements show greater solu-bility at elevated temperatures than.

The process of aluminium solutionizing treatment is slightly different to that of steel heat treatment. When the term is applied to aluminum alloys howev-. Solution heat treatment oven for Aluminum About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features 2021 Google LLC.

The elements most commonly present in commercial aluminum alloys for strengthening are copper magnesium manganese silicon and zinc. Solution heat treatment involves heating the aluminum and alloys to a temperature slightly below the eutectic melting temperature.

The process of taking a 6061 aluminum part in O condition to a stronger more durable condition begins by heat treating the parts at 985 degrees Fahrenheit for an hour in a drop bottom furnace.

The main processing methods include hot working cold working solution heat treatment aging treatment annealing treatment etc. Aluminum alloys are subject to work hardening also known as strain hardening. Aluminum Heat Treating Aluminum Solution Heat Treat-ing Aluminum alloys are classified as either heat treatable or not heat treatable depending on whether the alloy responds to precipitation hard-ening. A heat treatable Aluminum alloy is typically comprised of between two. The elements most commonly present in commercial aluminum alloys for strengthening are copper magnesium manganese silicon and zinc. Solution heat treatment solution. The process of aluminium solutionizing treatment is slightly different to that of steel heat treatment. Solution heat treatment involves heating the aluminum and alloys to a temperature slightly below the eutectic melting temperature. It is different in so much as the solution as treatment which involves heating the aluminium alloy up to its appropriate solution temperature followed by quenching rapidly this makes the alloy extremely soft.

The elements most commonly present in commercial aluminum alloys for strengthening are copper magnesium manganese silicon and zinc. The solution heat treatment involves heating the alloy to a high enough temperature to drive the alloy - ing elements into solid solution yielding a metastable supersatu - rated solid solution. Solution heat treatment solution. The process of taking a 6061 aluminum part in O condition to a stronger more durable condition begins by heat treating the parts at 985 degrees Fahrenheit for an hour in a drop bottom furnace. The general types of heat treatments applied to aluminum and its alloys are. Homogenizing is used to redistribute the precipitating elements more evenly throughout an aluminum part. Solution heat treatment is done by raising the alloy temperature to about 980 degrees F and holding it there for about an hour.

Post a Comment for "Solution Heat Treatment Aluminum"