Sheet Metal Gusset Design Guidelines

Sheet metal gusset design guidelines. The radius of. Sheet metal gussets are formed with special tooling which has a ridge going across the v opening. Followings are the important thumb rule in sheet metal design.

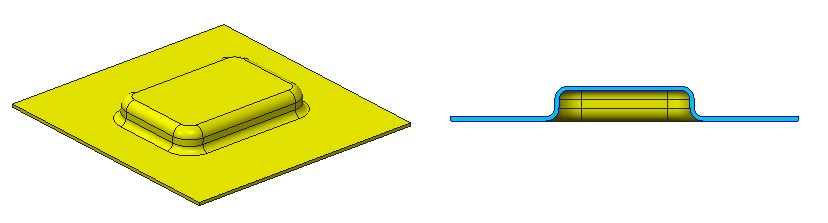

Design for manufacturability is a very useful concept in todays sheet metal design industry. Bends in sheet metal are manufactured using sheet metal brakes. When designing parts for laser cutting one should not make holes smaller than the thickness of the material.

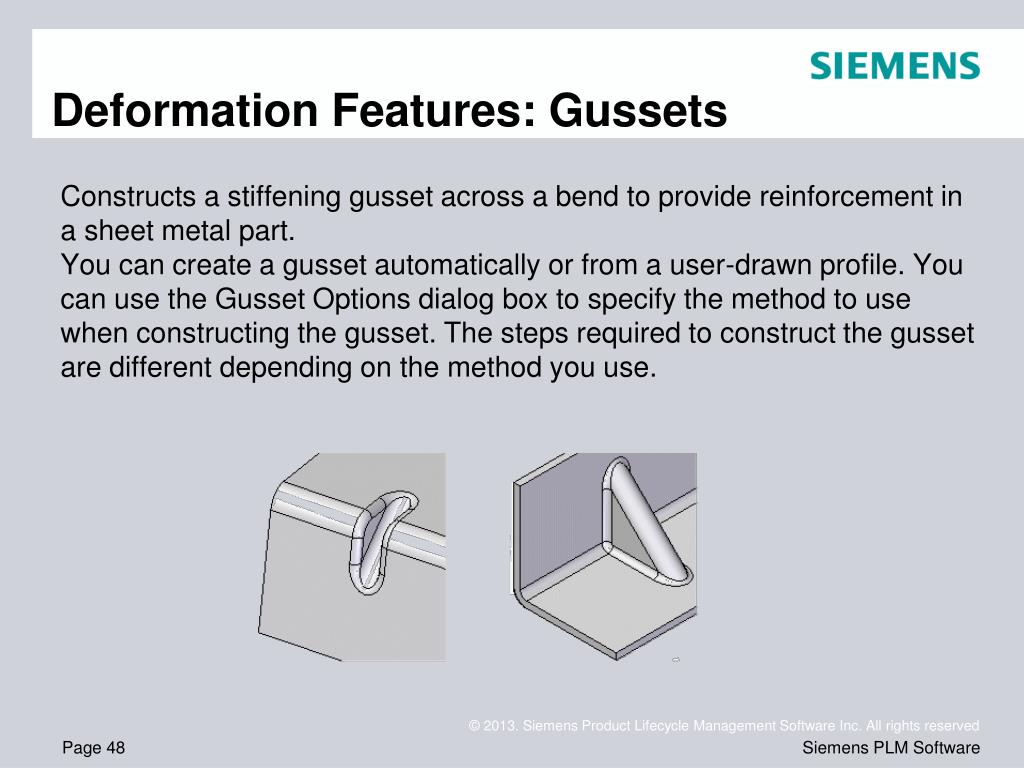

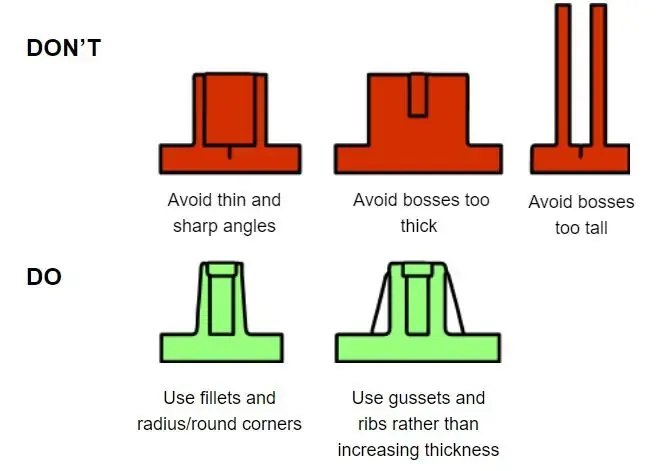

45 gussets shouldnt be designed to be more than 4 times material thickness on their flat edge. The width and depth recommended at an angle of 45 degrees is directly proportional to the radius and material thickness. All design guidelines can not be followed in one part.

The minimum distance that a gusset should be from the edge of a hole iin a parallel plane is eight times the material thickness plus the radius of the gusset. Hems The minimum diameter of a teardrop. So you decided to design your own sheet metal part.

Gussets are used to strengthen a flange without the need for secondary processes such as welding. Gussets The width and depth recommended at an angle of 45 degrees is directly proportional to the radius and meterial thickness. The punch is split to the left and right of the ridge as to not be damaged while forming.

Hems are used to create folds in sheet metal in order to stiffen edges and create an edge safe to touch. Edge Flange Design Consideration. Modules of rupture A sheet metals ability to withstand stress in a flexure test is an essential facet of sheet metal design.

Sheet Metal Guidelines This document attempts to address the most common issues and best practices for sheet metal design and fabrication at Demtool. In low carbon steel sheet metal the minimum radius of a bend should be one- half the material thickness or 080 mm 003 inch whichever is larger.

We will assume that the loading that you are designing to is a static load as described below.

The width and depth recommended at an angle of 45 degrees is directly proportional to the radius and material thickness. Hems The minimum diameter of a teardrop. Wear resistance good conductive properties and stability. P1 Distance Between Two knockout 5 D mm. Edge Flange Design Consideration. Followings are the important thumb rule in sheet metal design. Minimum distance between knockout feature and bending edge is maintained to avoid metal deformation. In low carbon steel sheet metal the minimum radius of a bend should be one- half the material thickness or 080 mm 003 inch whichever is larger. The punch is split to the left and right of the ridge as to not be damaged while forming.

Design Guidelines SheetMetalMe When adding a Curl to the edge of a sheet the following guidelines will ensure that no special tooling is required. Use the following simple guidelines to formulate and design the type of sheet metal bracket you will need to successfully meet your requirements. The starting point is determining what loading your metal part will be required to hold. 7 Must-Follow Sheet Metal Design Guidelines. Edge Flange Design Consideration. T Sheet metal thickness h depth of gussets W width of gussets. Bends specified as angles may be tolerance at plus or minus one-half degree at a location adjacent to the bends.

Post a Comment for "Sheet Metal Gusset Design Guidelines"