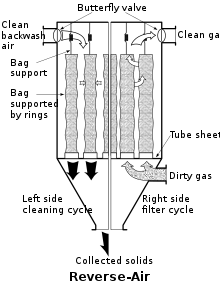

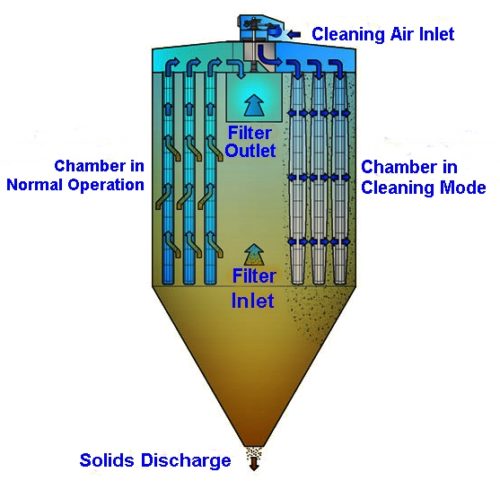

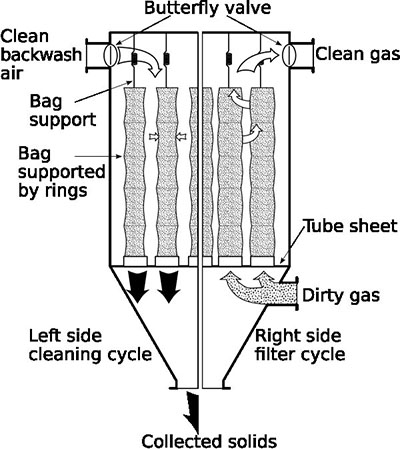

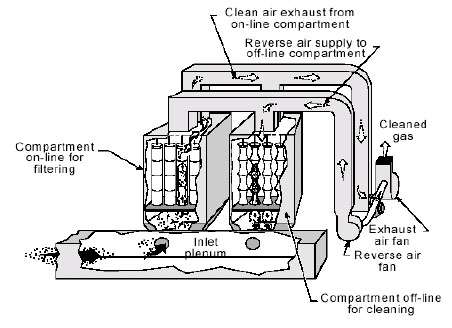

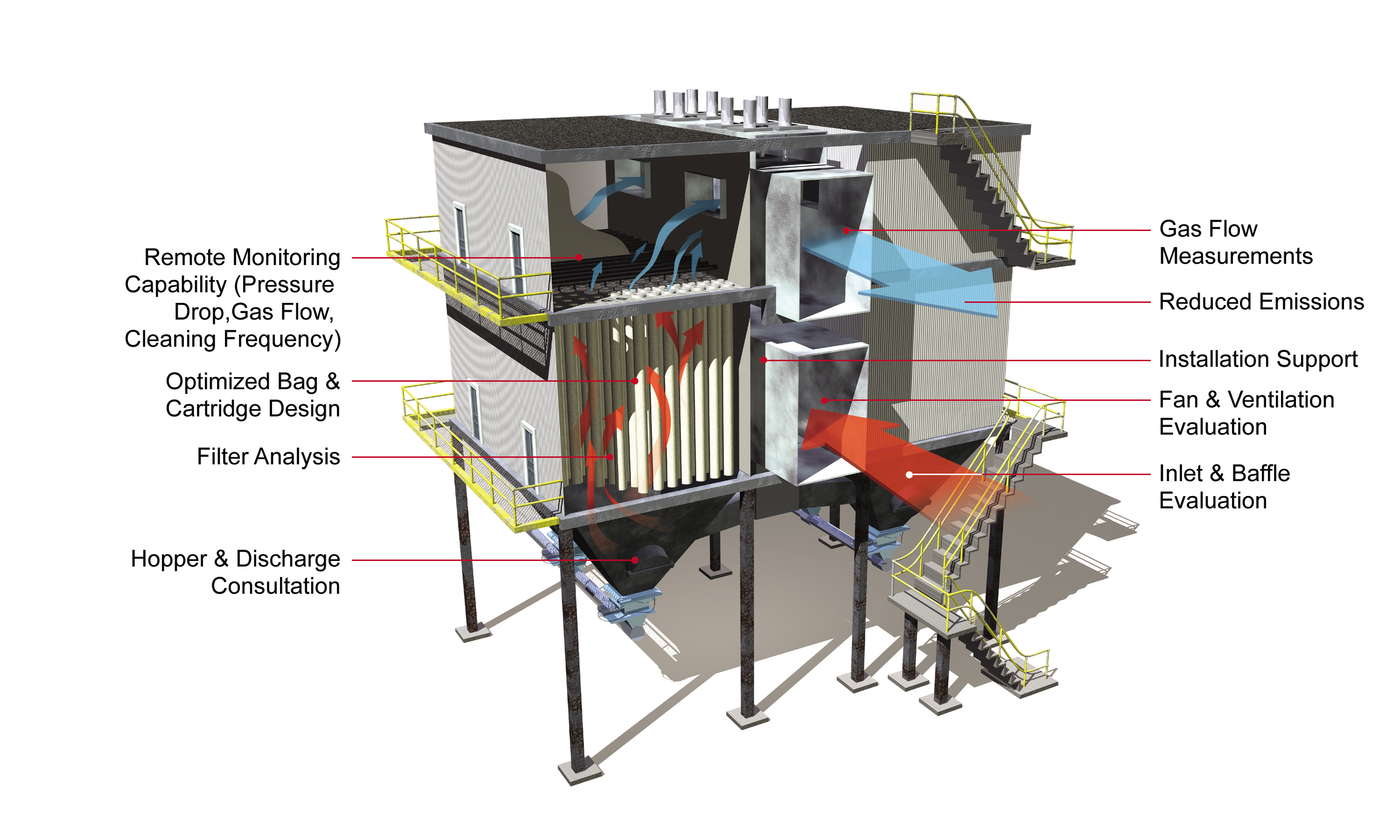

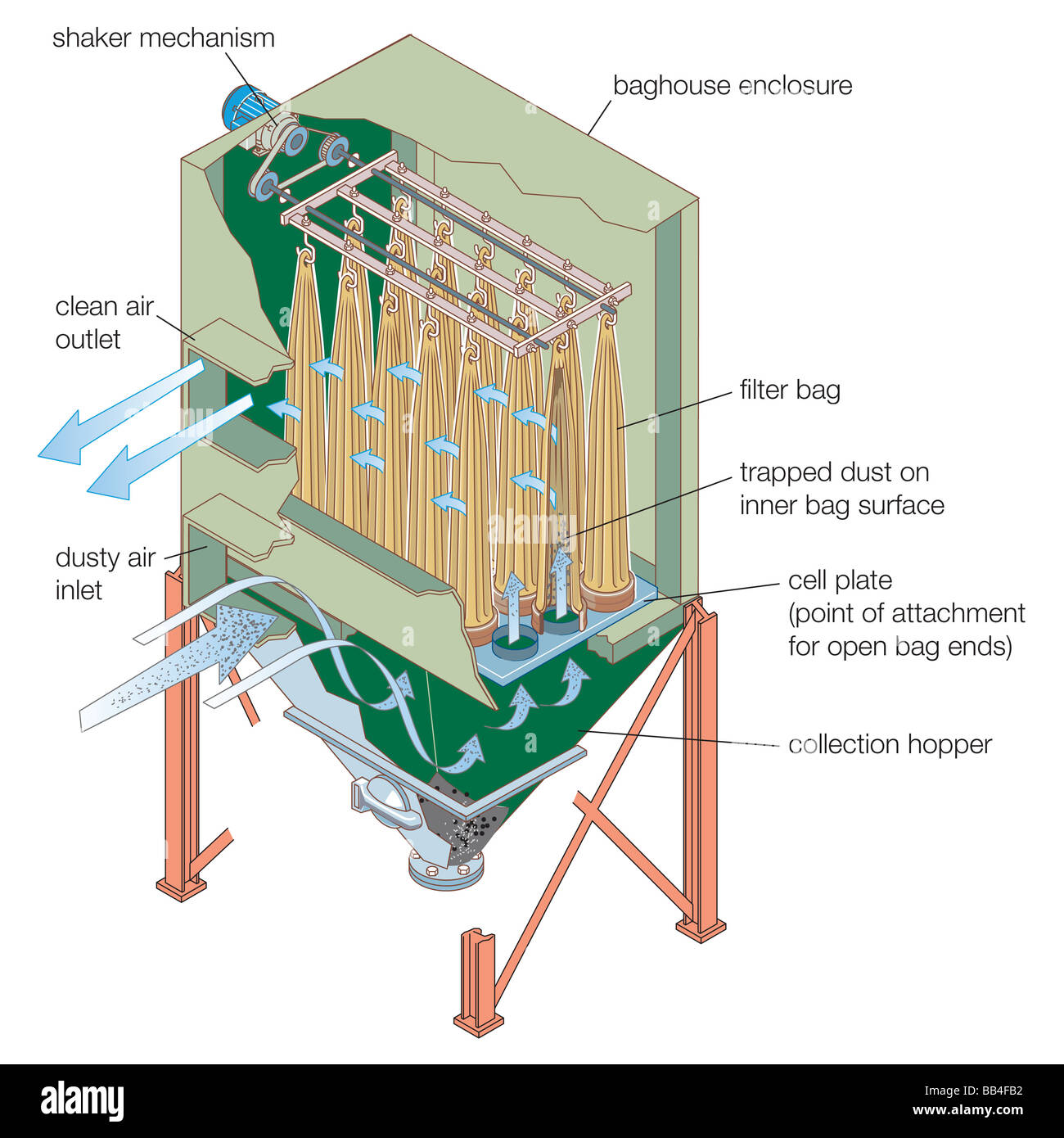

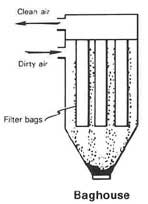

Baghouse Filter Diagram

Baghouse filter diagram. To ensure the filter bags have a long usage life they are commonly coated with a filter enhancer pre-coat. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators. With proper maintenance the dust collection system as a whole will function more efficiently and have consistent air flow.

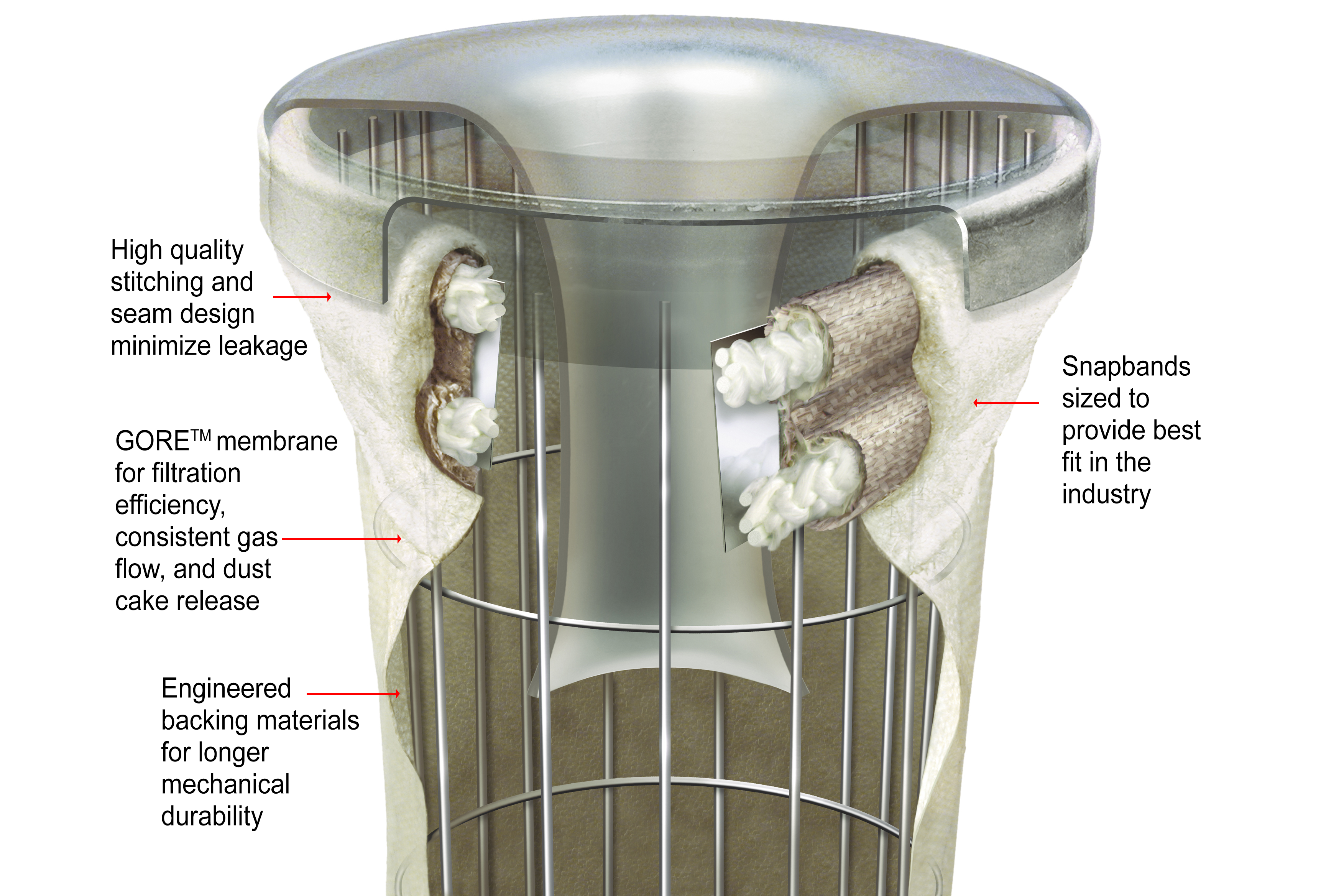

These filters are typically made of matted fibers mounted in supporting frames. A critical component in baghouse efficiency is properly maintaining its filters. Also regular maintenance reduces the.

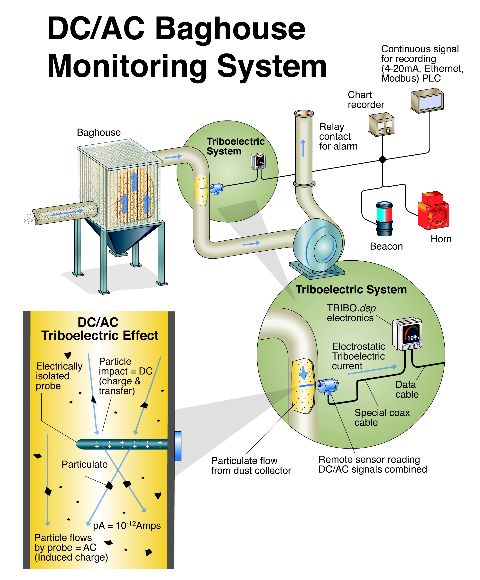

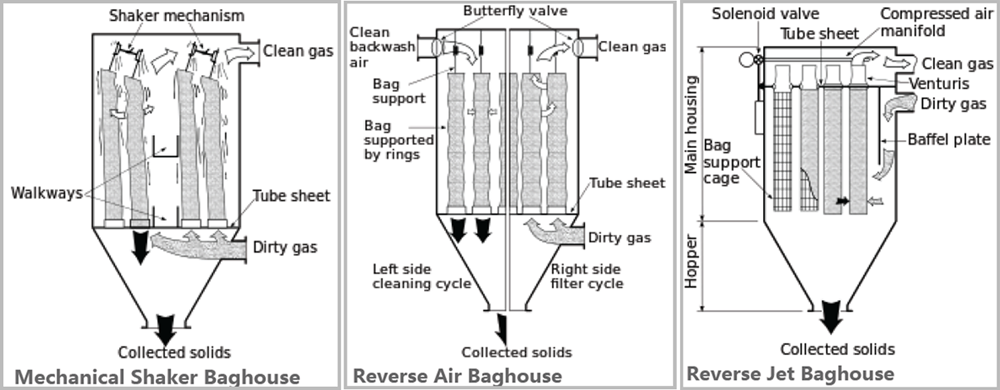

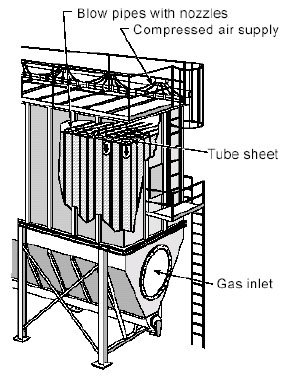

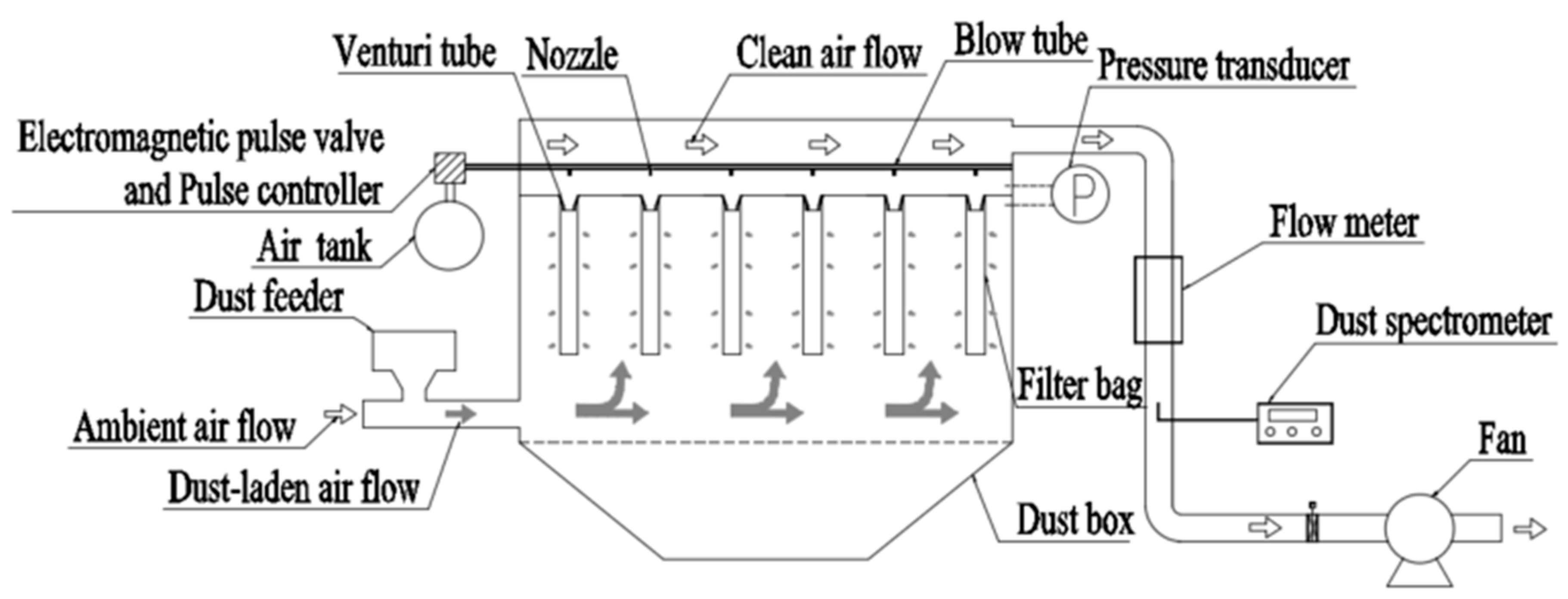

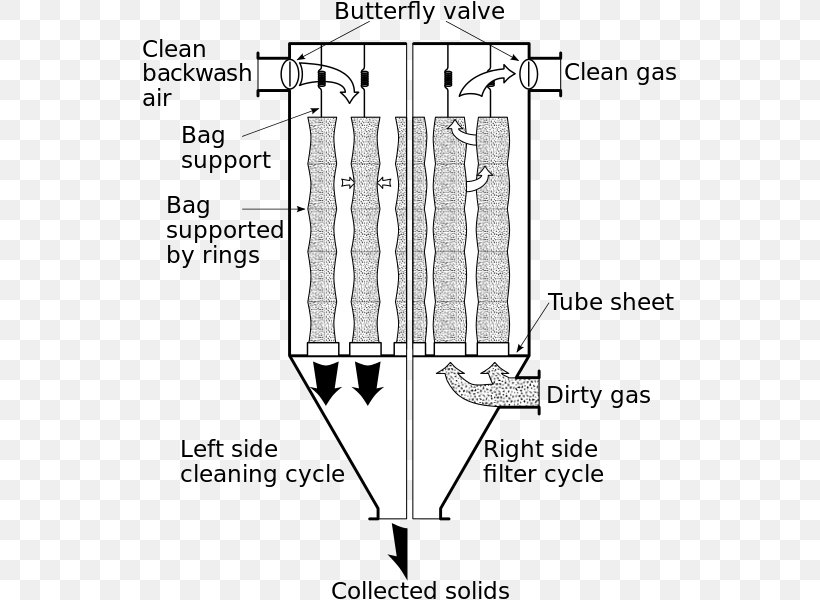

Care must be taken. Diaphragm pulse valves are the most important components of a baghouse pulse jet cleaning system. Most filter bags will burn if exposed to sparks welding or open flames.

Before entering any dust collector. This Pulse-Jet baghouse design can accommodate 6 meter to 10 meter long filter lengths ranging from 535 dia up to 6 dia and 2-piece cages. Power plants steel mills pharmaceutical producers food manufacturers.

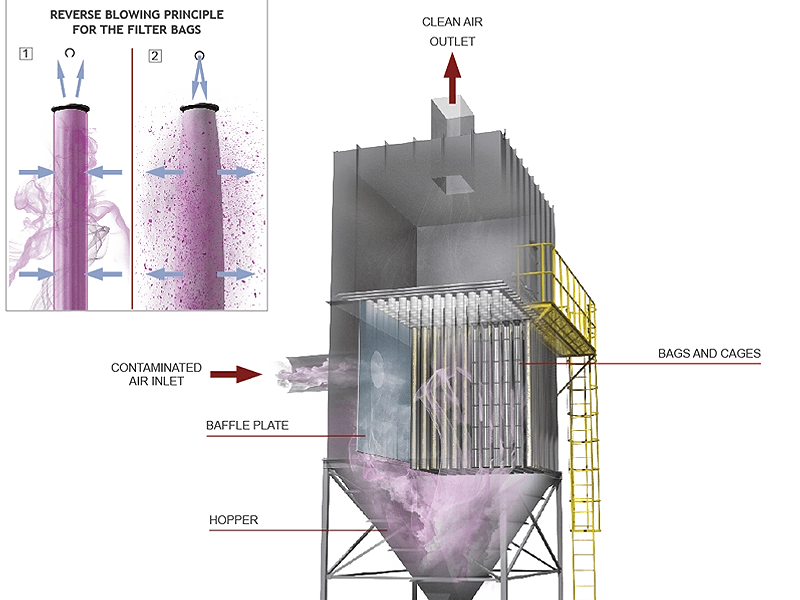

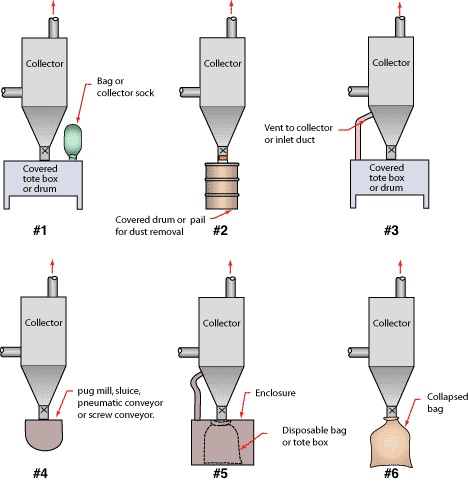

Dust Collector Control Boards. Shut off compressed air blower supply and relieve pressure in the. The bags can be of woven or felted cotton synthetic or glass-fiber material in either a tube or envelope shape.

Run cleaning mechanism 20 minutes with the fan off to clean filter bags. With so many different types of baghouse filter fabrics and treatments options to choose from its important to know which is the best fit for your specific application. When the baghouse control board or timer board initiates a cleaning cycle it sends an electrical signal to the.

Why baghouse maintenance is important Increasing efficiency. Air pollution is the introduction into the atmosphere of chemicals particulates or biological matters that cause discomfort disease or death to humans damage other living organisms such as food crops or damage the natural environment or built environment.

A critical component in baghouse efficiency is properly maintaining its filters.

With so many different types of baghouse filter fabrics and treatments options to choose from its important to know which is the best fit for your specific application. Thats because it takes a greater amount of energy to pull air through dirty filters. Baghouse America manufacturers baghouses and ships them all over the globe. Choosing the correct baghouse filter will maximize performance increase filter life reduce system downtime and save you money. Dust-laden gases enter the baghouse and pass through fabric bags that act as filters. Why baghouse maintenance is important Increasing efficiency. Dust Collector Control Boards. When the baghouse control board or timer board initiates a cleaning cycle it sends an electrical signal to the. A baghouse bag filter or fabric filter is an air pollution control device that removes particulates out of air or gas released from commercial processes or combustion for electricity generation.

Completely discharge dust solids from hopper if applicable. Why baghouse maintenance is important Increasing efficiency. The use of chemically. Most filter bags will burn if exposed to sparks welding or open flames. A baghouse filter is basically a sequence of fabric or composite filters that polluted air passes through. This parameter is. Care must be taken.

Post a Comment for "Baghouse Filter Diagram"